CHEMICAL + PHYSICAL VAPOUR DEPOSITION

CHEMICAL (CVD) and PHYSICAL (PVD) VAPOUR DEPOSITION

PVD and CVD are two processes used to produce a very thin layer of material (known as thin film) onto a substrate. Vapor deposition techniques are the preferred processes for thin films because the techniques produce products with superior hardness, wear resistance, smoothness and oxidation resistance. Thin films made through vapor deposition are typically able to function in unique, high-stress environments.

These processes have many applications in a wide range of industries, such as aerospace, automotive, dies and moulds for all manner of material processing, cutting tools, firearms, optics, photovoltaics, watches, jewellery, thin films (window tint, food packaging, etc.), darts barrels, metals (aluminium, copper, bronze, etc.).

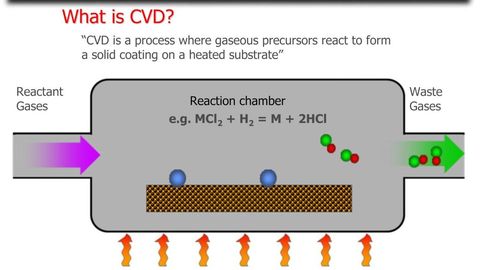

Example of CVD process, where gaseous precursors react to form a solid coating on a heated substrate

Many variables exist in CVD and PVD reaction processes. For example, as described by Chen et al. (2019), controllable synthesis of MoS2 with desired grain morphology via CVD or PVD remains a challenge, and it is therefore important to understand polycrystalline growth of MoS2 and further provide guidelines for its CVD/PVD growth. The authors formulate a kinetic Monte Carlo (kMC) model aiming at predicting the grain boundary formation in the CVD/PVD growth of polycrystalline MoS2.

In order to help R&D teams in relevant industries to optimise product efficiency and performance, FACSIMILE kinetic modelling describes the reaction kinetics, providing tools to better understand and describe CVD and PVD processes. As chemical processes, CVD and PVD are relevant to chemical kinetics.

For more information on direct chemical kinetics example applications, follow the FACSIMILE Applications links: